The oblique impact test evaluates the shipping container, inner packaging, or both, to protect the contents when subjected to impact. Shock testing also evaluates differently designed vessels of the same size and carrying the same load.

As an ISTA and ISO 17025-accredited laboratory, Linkotest recognizes the importance of inclined impact testing. Meeting tilt impact compliance requirements can be difficult. Throughout the process, we guide companies through the challenges.

With our expert engineers, you can rest assured that all your needs will be addressed under one roof. When packages do not meet requirements, we assist in finding solutions. Linkotest employs a negotiated approach throughout the testing program.

Request a quote and learn firsthand about our competitive pricing, timely process and reputation for excellence. Have questions about impact compliance testing? We will determine the best course of action if you contact us.

1. Why is Inclined Impact Testing Important?

The compliance packaging test simulates handling and distribution impacts in the laboratory. In addition to observing progressive failure of the package, impact testing allows for damage to the contents to be observed as well.

Procedures in this test type can produce severe mechanical responses. As a result, packaging affects far more than product replacements, shipping claims, and customer satisfaction.

On the other hand, the benefits of testing packages to withstand shipping hazards may include:

- Balance Allocation Costs

- Confidence in product launches

- Increased customer satisfaction and growing market share

- Reduced time to market

2. Tilt Shock Package Test Procedure

The oblique impact test procedure begins with sample selection and conditioning. A specified number of samples is selected to accurately represent the partial units manufactured. Conditioning testing is recommended for ASTM D4332: Conditioning of Containers, Packaging, or Packaging Components.

There are two procedures for this type of testing. Procedure A: Test the ability of the container to withstand impact, and Procedure B: Test the ability of the container, shipping unit or inner packaging to protect the contents.

Program A:

First, the container is placed on the carrier with a surface or edge that will take impact beyond the impact end of the carrier. Depending on the purpose of the test, it continues until it fails. A failure is defined as the occurrence of a predetermined type of damage. This includes exposure or spillage of the contents or both.

Program B:

This test method is performed similarly to Procedure A. However, it continues until a predetermined number of impacts are applied at a specific impact velocity. Then open the unit and inspect the contents.

Finally, after the test is complete, a report is written with the following test information:

- Sample description

- Description of content

- Determine the purpose of the test

- conditioning method

- test sequence

- detailed test results

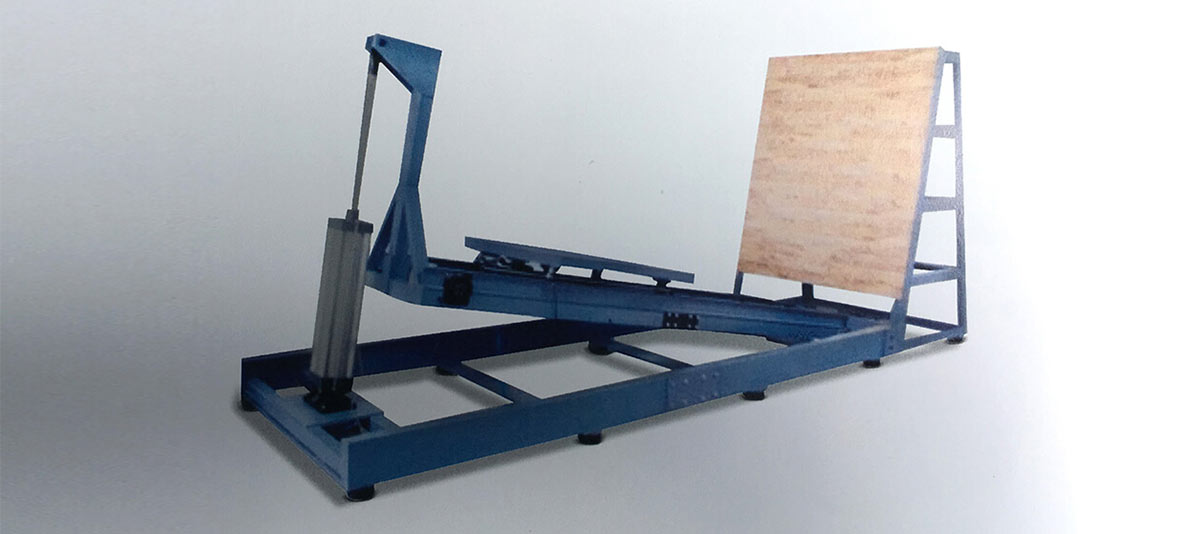

3. Linkotest Tilt Impact Capabilities and Equipment

Keystone’s testing machines are capable of precise drops from various heights and angles. Our new packaging testing laboratory includes multiple compression testers. We use dozens of climate chambers ranging in size up to 1,300 cubic feet with shakers up to 12 kips.

Plus, our testing facilities give you peace of mind knowing that all your packaging testing needs can be met under one roof. We can test flexible and rigid packaging in a variety of sizes.

4. Expert Inclined Impact Tester Lab

In addition to oblique shock testing, Linkotest has comprehensive expertise including drop, cold chain, and vibration integrity testing. Our team strives to give our customers more time and energy to spend on product development rather than testing. We can accommodate soft and hard bags of all sizes.

Leave A Comment