When working in an intense environment such as a factory, there is an underlying need for stringent safety measures. This ensures the protection and safety of everybody involved in the factory’s day-to-day running. One safety measure that can be implemented with many benefits is pedestrian safety barriers.

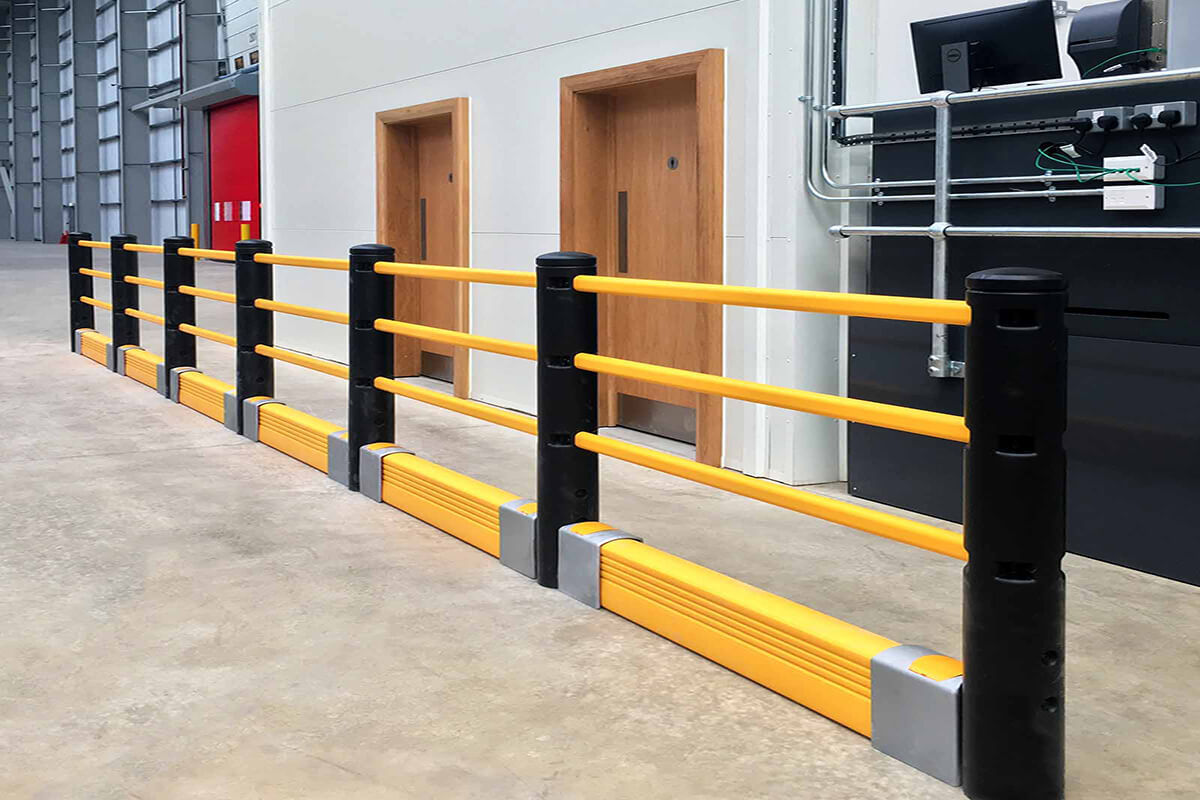

Safety barriers are handy in a number of scenarios and we have compiled a useful list of the key advantages that they can bring to your workplace. Their modular design and easy installation make for a flexible piece of protection that can shield your most important assets from damage in the event of a collision. Read on to see just how important a safety barrier can be for your business.

1. Stock protection

Factories nowadays tend to stack their products vertically rather than horizontally, to allow for more stock to be stored within a particular space. However, the higher you store your items, the more at risk you are of harm to yourselves and damaging the products as well. Warehouse guardrails give a helping hand to your vehicle drivers to be more vigilant of possible incoming pedestrians, although this should be covered in depth in their vehicle training.

Remember, in the event of any collision, you want to ensure minimal damage occurs to all parties involved. Without the implementation of a safety barrier, for example, the potential damage can be extremely costly. This includes vehicle repairs/replacements, injuries to your workforce, and if a vehicle collides with your stock – product damage. Calculate these scenarios up and you have one hefty bill, all for the sake of one accident that can be avoided.

Our safety barriers are cost-effective protection solutions, easy to install, and even easier to modify to your specific requirements. Once installed, their vibrant color will stand out across the factory and act as a warning for everybody involved. Reduce the likelihood of an accident radically and feel safe at the same time!

2. Pedestrian safety

As much as your vehicle drivers need to be vigilant about potential hazards, so do your pedestrian workers. Potentially, your on-feet workforce are most likely at risk due to the mileage they cover in a typical working day. Their concentration levels must be at their peak to keep themselves safe. The presence of safety barriers will not only reassure your workforce that their safety is paramount in the eyes of the management team, but will act as an indication to watch out for incoming vehicles.

However, this can sometimes be tricky. For example, if a pedestrian worker is carrying stock incorrectly, such as overhead height, they are reducing their vision and therefore increasing the likelihood of a collision, slip, trip, or fall. Should this occur in racking or other stock, it could be quite a nasty injury for your worker. This obstacle should be overcome with the use of correcting lifting and carrying procedures, but the sight of a pedestrian safety barrier will offer an extra layer of protection.

Pedestrian workers themselves can also make sure that they are just as visible as the safety barriers. The most common form of workforce safety in a factory is the use of Hi-Vis clothing, meaning they can be seen from a distance and in the vehicle driver’s peripheral vision.

3. Vehicle protection

As important as it is to protect your assets, your vehicles should be equally protected. As mentioned briefly above, equipment such as vehicles can become the victim of a collision and therefore extensive repairs are needed. This is the case even if you have a level of protection installed, for example, a traditional steel barrier. These types of barriers send the force of the collision back toward the source of the impact, which writes off your vehicle entirely. It also leads to further damage to your floor due to the way a steel barrier must be installed.

With an Aotons safety barrier, you are removing the risk of extensive damage. It’s core material means that any collision force is dispersed amongst its own body, rather than back to the source of the collision. This radically reduces the damage caused to the vehicle and the vehicle driver involved. What this also reduces is damage to the floor. There no longer needs to be time and money dedicated to repairing the floor surface area surrounding the barrier!

4. Racking protection

Because most factories prefer to stock vertically rather than horizontally, there is more racking in warehouses than ever before. In some cases, the racking can simply go from the floor to the ceiling, meaning workers could end up working at some dangerous heights. Not only is the safety of the worker at risk, but in the event of a collision down below, if there isn’t a safety barrier in place, it could cause the racking to come away from the wall and cause a domino effect with the rest of the racking. Needless to say, this can lead to a Health and Safety nightmare.

There are ways you can reduce the risk across the board. First and foremost, it is pivotal that your racking is securely fixed to the wall and of an acceptable, safe height – therefore rendering your racking unable to move when it encounters any impact. Secondly. A safety barrier down below will act as a shield between the vehicle and your racking, meaning no damage is caused to either due to the barrier’s ability to absorb the shock. Thirdly, adequate protection for the worker when working at height, for example caging for them to safely stand and work within, can be crucial to the well-being of your workforce.

5. Machinery protection

Machines in factories can be expensive at the best of times and therefore a lot of work is put into keeping them safe from danger. However, an accident can occur from nothing sometimes. All it takes is a careless maneuver or turn that leads to a vehicle driver losing control of his forklift and heading straight toward a piece of machinery.

Areas that are designed for the storage and location of machinery should be protected with a safety barrier. Much like how they protect the racking, a safety barrier acts as a shield between the vehicle and the machinery. Replacing your vehicle in comparison to replacing your machinery puts this into perspective, but with our barriers, neither needs to be replaced. If your vehicle is operating within the UK law speed limit for an interior workplace, the damage is nothing more than aesthetic damage to the paintwork. Our barriers are designed to not only prevent further damage but also absorb the shock of any collision.

Wherever it is possible to install a cost-effective layer of protection, it should be considered. A slapdash attitude towards factory safety will only lead to accidents and some very expensive repair work. Don’t allow your factory to be disturbed by maintenance work and allow yourself to operate as normal, knowing you’re in the safest environment to do your job in.

6. It all comes down to health and safety

What we’re trying to deliver here is the importance of excellent Health and Safety. It is imperative that every company has a stringent Health and Safety policy for all workers to abide by. Your policy is essentially your core safety measure, presented to your staff as an indication as to how important their safety is to you.

However, further safety measures like our range of safety barriers act as further layers of protection and safety, meaning that with every installation of one of our products, you’ll be further reducing the likelihood of a workplace accident. Remember, it is impossible to have too much protection, as accidents can occur in the simplest of scenarios. A slip in concentration and suddenly it’s too late! If everybody working within the factory is on the same page when it comes to workplace safety, you’ll see the difference in no time.

7. Conclusion

This guide summarizes 6 key advantages of using pedestrian safety barriers in the factory, which shows the importance of using safety barriers in the factory. Finally, to install a professional safety barrier, please contact a good safety barrier manufacturer.

Leave A Comment